SPECIFICATIONS

Automation: Automatic

Brand Name: NoEnName_Null

Certification: CE

Control system: tp10s

Dimension: 1700x900x1650

Extra Services: Machining

Hign-concerned Chemical: None

Is Smart Device: Yes

Machine Type: Press Brake

Material / Metal Processed: Stainless Steel

Model Number: WC67Y/K-125/3200

Origin: Mainland China

Power (W): Cnc

Raw Material: Sheet / Plate Rolling

Warranty: 2years

Weight: 1.5t

distance between housing: 1280mm

length of table: 1200mm

main motor: 5.5kw

norminal pressure: 40t

ram stroke: 80mm

throat depth: 200mm

WC67Y 40T 1200MM CNC Press Brake with TP10S, Hydraulic Bending Machine with Laser Protection Device

Products Description

Press brake is a kind of machine specially in bending plate, mainly used in automotive manufacturing, kitchen appliance

manufacturing, electricity poles, lamp posts, ship-building, military industry, steel industry, mechanical manufacturing. Bending

dies can be designed and changed according to customers' different needs.

Main types of press brake produced by our company are: manual torsion, CNC torsion press brake, electro-hydraulic press brake,

large electro-hydraulic synchronization press brake Currently, our biggest press brake equipment is 1000T/10000, production for

many years, and stable performance.

Main Feature

All the components of the machine are designed under the instruction of the Computer aided design and software of CAD/CAE/CAM to

fully guarantee the intensity and rigidity of all the components.

2.The whole body under total wielded, thickness and reliable in machine body with high-rigidity and good in shock absorption

reduction.

3.The machine structure are composed by body frame, working table, slide block, main cylinder and backgauge.The advantage design

and produce style can ensure the machine usage and high precision.The main produce procedure as below(all process under strictly

inspection)

4.Plate stock----physical and chemical inspection----Plate Pre-treatment (Rust-Cleaning) --- CNC flame Cutting-- Cutting the

welded joint----Group Welding----Gas Shielded Welding---Ageing treatment----Milling Planer working----The Assembly of finished

products

5.The machine body, Slide Block, Working table and other main components are under one time clamping of large landing boring and

milling machine to ensure several geometric accuracy of the main machine.

6.The machine is greatly enhanced in anti-torque and electronic load resistance. Machine can normally work in full loaded

situation. Working table, Upright Column, Crossbeam and Ram are good and high in design rigidity. Little deformation between the

working table and ram when work to guarantee good straightness and uniformity in angle

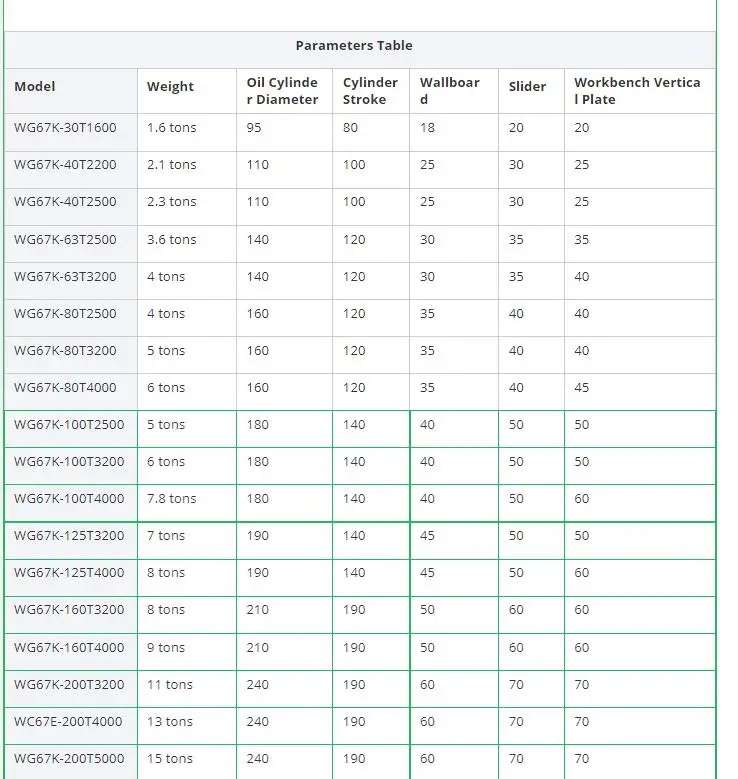

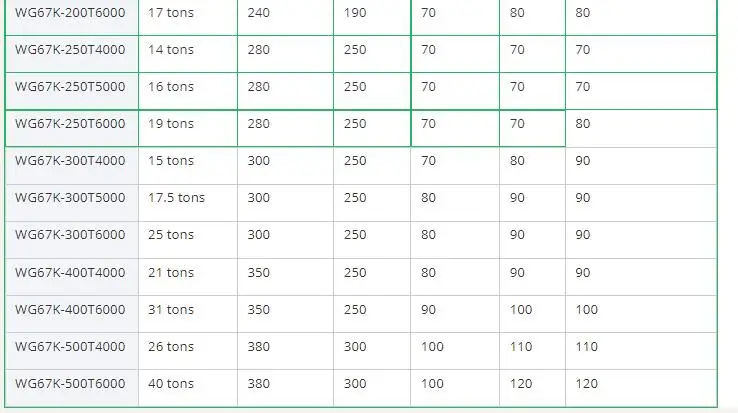

Product Parameters

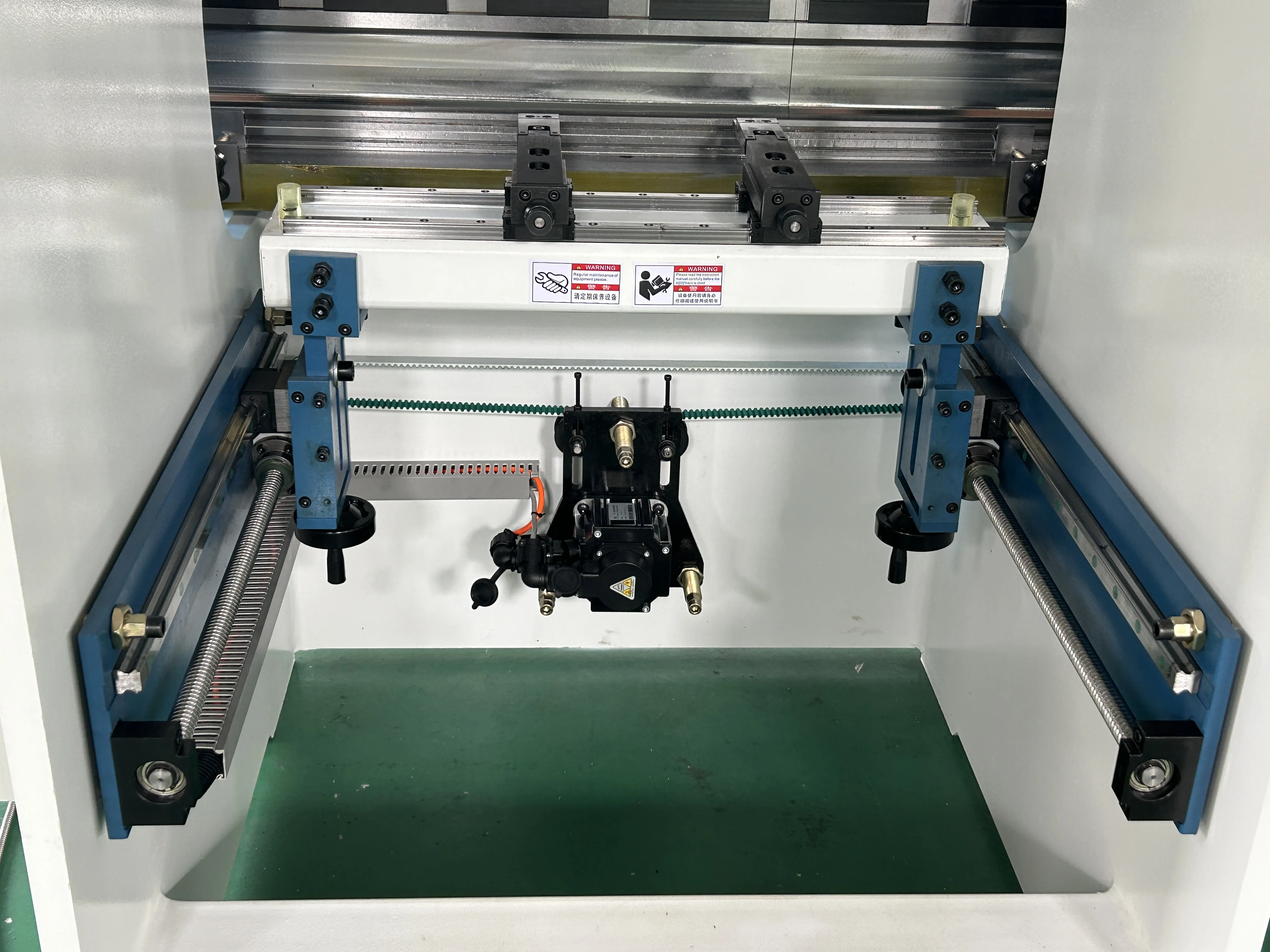

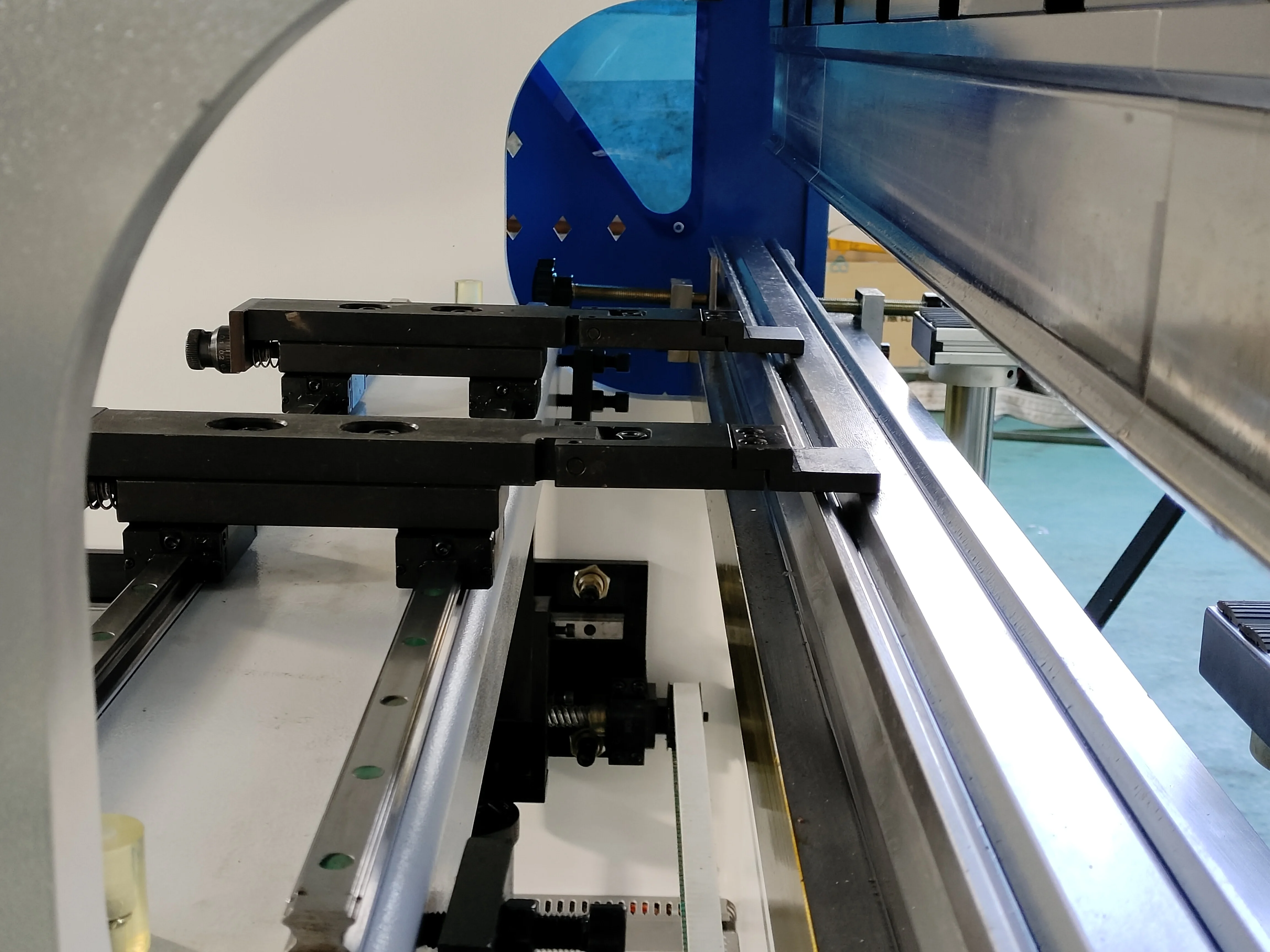

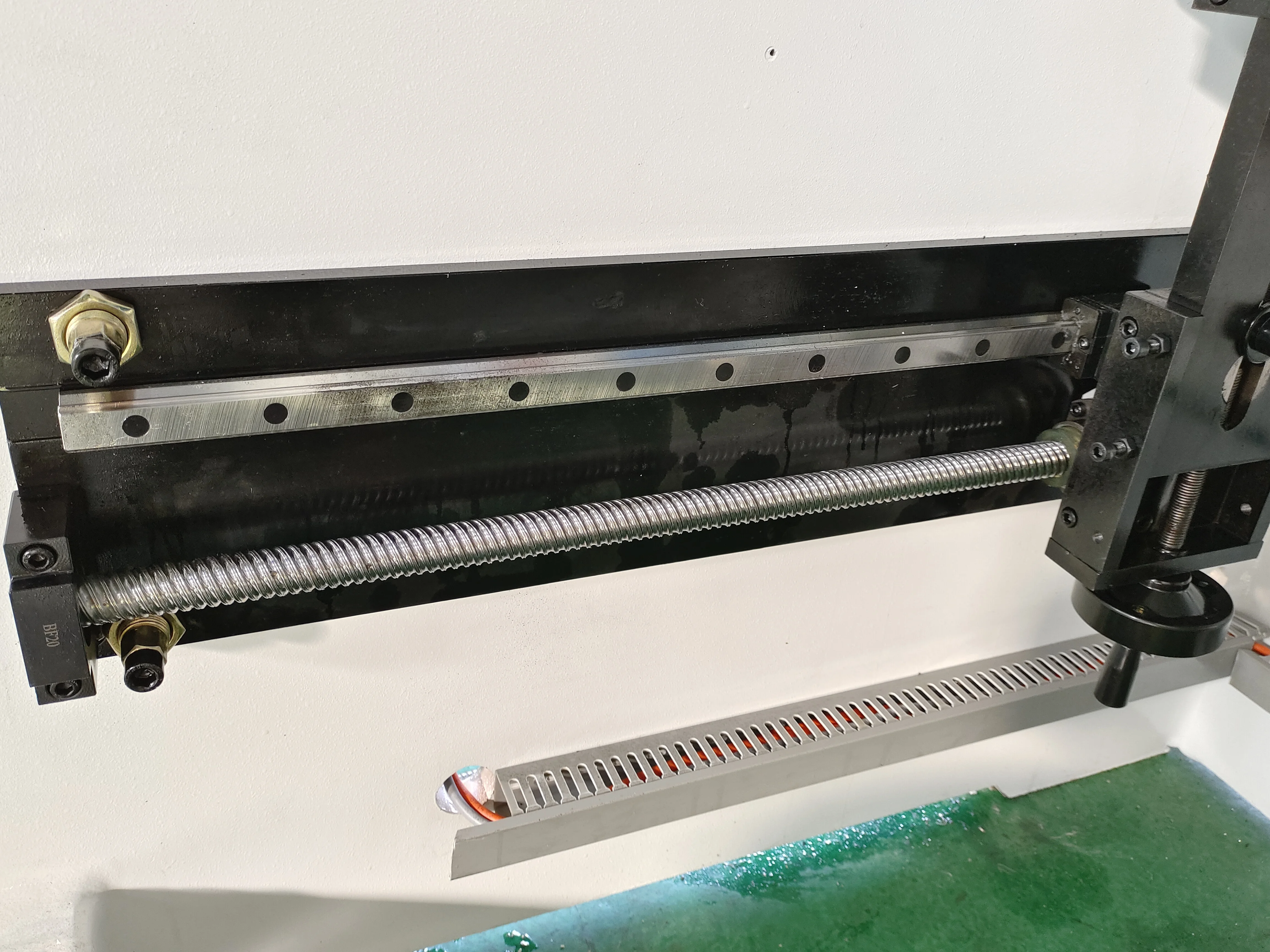

Detail Pictures

main motor

foot switch

foot switch

fast clamp

Ball screw linear guide

Ball screw linear guide

Laser protection device (optional)

Laser protection device (optional)

Control System

1. 7 inches TFT colorful touch screen and high-contrast

2. Intuitive and user-friendly interface

3. Simple pages,

large keys, easy for operating

4. Faster and reliable CAN communication between controller and drives

5. Convenient wiring, easy for maintenance 6. Complete programming for efficient mass-production with multiple bends

7. Interactive warning display

8. English and Chinese languages available

Better Bending

◎ Angle and length automatic calculations of bend functions

◎ Angle and length correction

◎ Configurable retraction

of the back gauge during the bending process ◎ User friendly graphic tool management

◎ Bending steps and programs can be memorized Powerful

◎High reliablility and anti-jamming capacity

◎ A configuration table for valves sequencing ◎ Software stroke limit

◎Easy manual movement (Password protection)

◎ Wizards of X/Y axis (Password protection

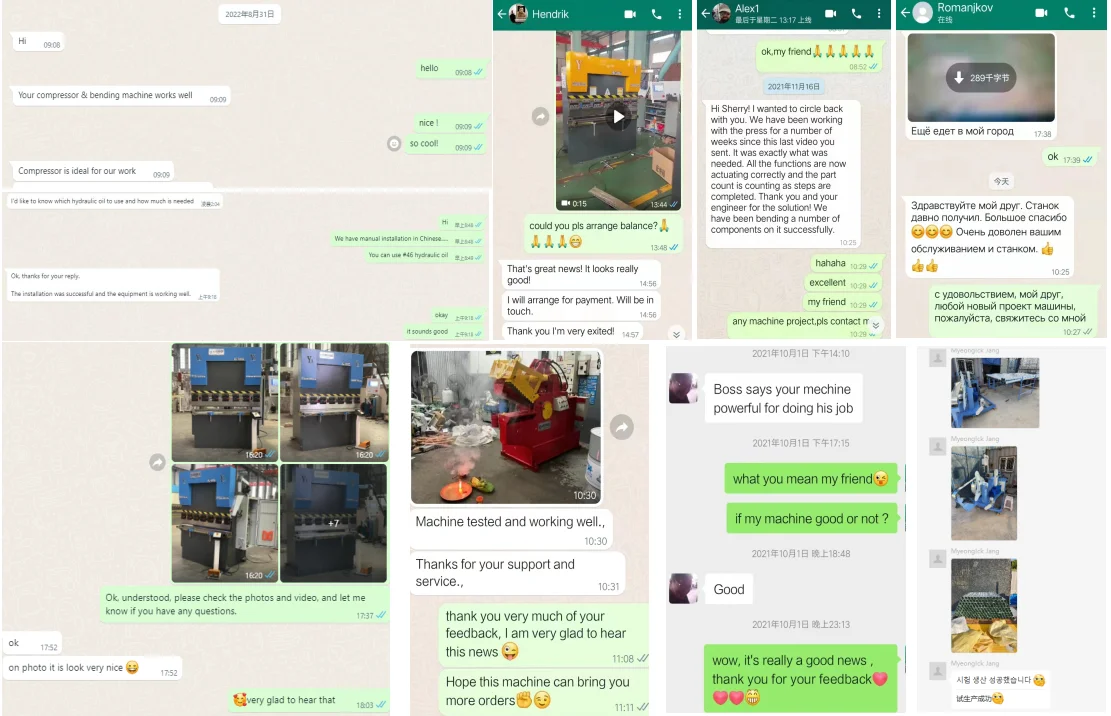

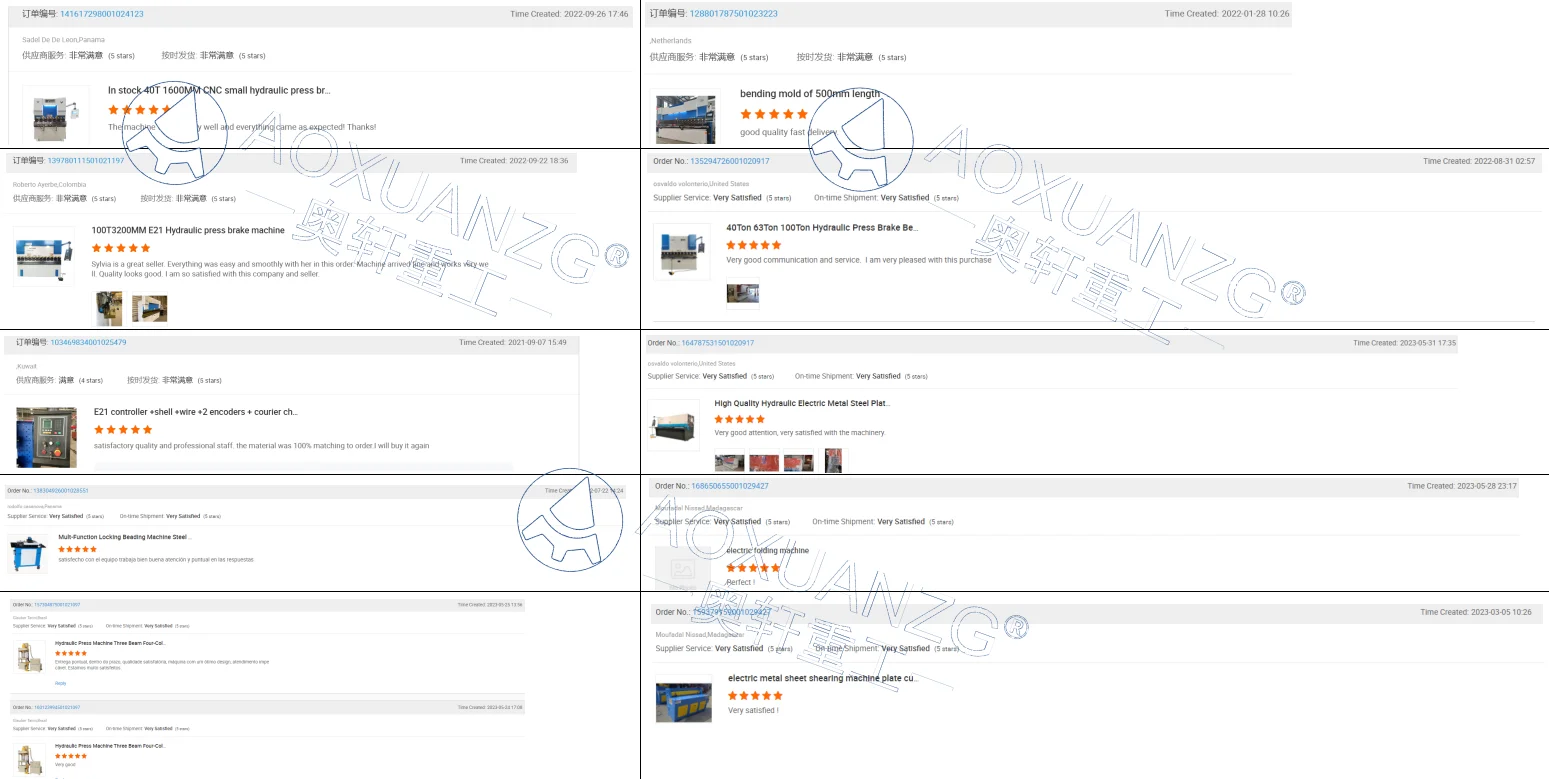

Good Feedback

Certificates

Packing & Delivery

Packing Detail:

Each Hydraulic Bending Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail :

☀ Shipped in 30 days after payment

pack in wooden case

Our Workshop

Our Customers

RFQ

1. Are you the manufacture?Can we visit your factory?

We are manufacturer and we are located in Anhui,China.And we have our own design team for products design.

And welcome you visit our factory and check our machine qualtiy on spot,any question will be solved on spot at first time.

2.What's your main product and what is your main foreign market?

Our main products are press brake,shears machine,press,cutting machine,locking machine ,auto duct line and related products.

Our main foreign market are Asia, North America, Europe, Africa.

3. What are the advantages of your machines?And how can i believe the quality of your product?

The main configuration is to import quality products, and Professional product quality inspection teamensure machine in

top-quality, precision and life.

For example,Germany Bosch-Rexroth Valve group,Germany Siemens Main Motor,Schneider Electrics system and so on.

Once tested as qualified .our machine would be sent out.So The quality of our product is stable and reliable.

4. And are you able to update the production process Information in time after placing our order?

After confirming your order ,we would keep you updated of production details of emails and photos.

5. Can we be your agent?

Yes,we are looking for Global agent we will help agent improve the market ,and supply all the service like machine technical

problem or other after-sales problem, meanwhile ,you can get big discount and commission.

6. Payment terms?

T/T, L/C, Western Union, Paypal, Alibaba Secure Payment ect.

Buyer pays 30% by T/T to start this order, rest 70%paid before shipment.

7.Are you provide product metal parts and provide us technical guidance?

Wearing parts,Disassembly tool(free) are what we could provide.And we can give you technical guidance.Our technical staff can go

abroad to provide you with technical guidance.

8. How long is your warranty?

13 months free warranty, life-long maintenance.

9.Do you accept customer Logo and customized ?

we accept kinds of customized ,including logo and machine .

Contact Information

You may also like

Recently viewed

FAQs

Our approach on golf is making traning and improving at the game a fun and engaging experience on and off the course.

Join the Par Masters family today!

When will I receive my order?

We ship items within 2-3 business days of placing your order. Your order will arrive depending on the shipping method sleceted during checkout.

Free Standard Shipping 2-3 Weeks

DHL Express Shipping 5-7 Days

Please refer to our returns section: here